Expiration date of thermal paste: is it in the syringe, in tubes for processors

One user's laptop or computer works for many years without changing the thermal paste. Another person updates regularly, understands the importance of this aspect. Even manufacturers do not give a single service life. They set a range from 1 to 8 years. This should not be confused with expiration dates. The frequency of replacement depends on the intensity of use of the PC and storage conditions.

We will determine the shelf life of thermal paste and find suitable places for storage. Bonus - signs of an expired product.

What affects the shelf life of thermal paste for processors?

Air spoils the product the most. The mass dries out, changes consistency and cannot be applied in an even layer. Therefore, we recommend that you carefully monitor the tightness of the packaging and close it tightly after each use.

The second point is the composition. Metal oxides, nanodispersed powders, mineral oils, and liquid synthetic mixtures are used. There is no single formula. Some mixtures begin to deteriorate faster, while other formulas tolerate long-term storage.

The shelf life of ordinary thermal paste is 2-8 years. Directly depends on the composition and manufacturer. Once opened, if properly stored in an airtight container, it will not shrink. Do not use expired product.

Do you change thermal paste in your PC and laptop?

What is the expiration date of thermal paste?

There is GOST 19783-74. According to the document, silicone thermal conductive paste is stored for 18 months. Only modern companies are against such short shelf life. They introduce stabilizing additives, create convenient packaging, reliable, reusable caps.

Another question arises: does modern thermal paste even have an expiration date? Despite the additives, the mass loses its properties over time. How long it will work depends on the manufacturer. Let's look at the known species.

Shelf life of different thermal pastes:

- 36 months Alsil-3;

- 60 months Alsil-5;

- 8 years Arctic mx 4;

- 36 months CBT-8;

- 24 months Cooler.

Chinese thermal paste and gels with similar properties are often found. They perform well at work. Only the packaging does not indicate expiration dates. A prominent representative is Titan SG. The composition is excellent, the protection works perfectly. How much can be used and stored is a mysterious question. We hope the manufacturer will solve it soon.

In a tube

Most manufacturers prefer this type of packaging. The tubes are easy to use. Only the shelf life is practically not affected. It depends on the composition and storage conditions. It makes more sense to look at the information on the packaging of a specific product.

In a syringe

Such containers are used less frequently, although they are also convenient to use. The most commonly used thermal paste is Alsil. The shelf life is 36 months, less often increased to 60. To keep it unchanged, it is important to use a tight cap for the syringe.

Packaging does not affect the shelf life, composition, or quality. They choose solely according to their own preferences. Some people are used to squeezing thermal paste out of a tube. Other users are deft with the syringe.

How and where to store it correctly

Thermal paste is damaged by high and low temperatures and sunlight. But most of all it deteriorates in the air. Therefore, it is important to seal the tube tightly. It is advisable to provide additional protection - place it in a bag, wrap it with cling film, and pull a fingertip on the side of the lid. We recommend storing at room temperature 18-22 degrees.

Thermal paste in a syringe and tube

How to tell if thermal paste has gone bad

Expired thermal paste cannot be used. Like cement, concrete, wallpaper glue, the composition loses its properties. There is no point in applying useless thermal mass.

How to identify spoiled pasta:

- Open, squeeze out a small amount onto film or cardboard. Any item that you don’t mind throwing away will do.

- Check consistency. The mass should not thicken or dry out. Often the thermal paste delaminates and comes off. In this case, drops of liquid may appear from the tube when pressed.

- Consider. Blotches, lumps, and heterogeneity indicate spoilage.

There is no need to try to save the separated mass. Stirring will return it to its original appearance, only the product has already lost its protective properties.

Expired thermal paste does not protect computer parts from overheating. During active operation or gaming, serious damage may occur and components may burn out. Therefore, we recommend monitoring expiration dates. If you have the slightest doubt, it is better to renew the tube. It's inexpensive and will last for many years.

The second point is proper storage. Any item, be it a gas cylinder or diesel fuel, has its own characteristics of content. The easiest way to shorten the shelf life of thermal paste is to leave it in the sun, in the cold, and screw the cap on poorly. Often goods deteriorate during transportation and sit on the shelves of warehouses and stores.

Previous

Source: https://profhranenie.ru/srok-godnosti-termopasty

How to choose and apply thermal paste correctly

Laptop thermal paste is a popular consumable.

Both desktop and laptop computers require periodic replacement of the heat-conducting layer that protects the processor from overheating.

The average service life of the paste depends on the frequency of use of the device, and, as a rule, does not exceed a year: during this time, the paste usually either becomes clogged with dust or dries out.

Fortunately, the procedure for replacing thermal paste is not very difficult.

If you can disassemble and reassemble a computer, and then it still works, you can definitely handle replacing the paste.

Fig.1. Overheating processor. Fig.2. Distribution of thermal paste over the surface. Fig. 3. Variety of thermal pastes.

Fig.4. Cleaning the radiator and processor from thermal paste residues.

Fig.5. Correct amount of thermal paste Fig.6. Correct application of paste

Replacement frequency

You can determine that your laptop needs to replace the thermal paste based on the following signs:

- independent reboots and shutdowns of the device;

- increased boot time when turning on the laptop or waking up from sleep mode;

- slower response to user commands;

- increased noise from the cooler, causing discomfort during operation of the device;

- Rapid heating of the bottom cover and keyboard.

Fig.1. Overheating processor.

The principle of operation of thermal paste

Using thermal paste for a laptop processor allows you to avoid overheating and subsequent repairs to the chipset itself, motherboard or video card.

Although sometimes the same parts can overheat due to dust accumulated on them - in this case, not only replacing the paste, but also cleaning the laptop computer will help solve the problem.

Thermal paste, also called a thermal interface, is a connecting link between the heat exchanger and the processor, increasing the efficiency of their operation.

The purpose of the material is to fill the gaps and irregularities between the heatsink and the top of the chipset, which guarantees the normal operation of the laptop's cooling system.

What it is?

Thermal paste is a multi-component element that is in a flexible plastic state. Due to its properties, it serves as a good thermal conductor, so it is often used to reduce the temperature resistance between the touching surfaces of computer parts. In other words, KPT-8 thermal paste fills all the unevenness of the radiator and processor, thereby reducing their heating (by several degrees). It is worth noting that outwardly this cavity may seem absolutely flat. But that's not true. If you look closely (preferably through specialized tools), you can see many depressions and microcracks. During operation, they create a kind of air cushion that interferes with normal heat removal. As a result, the processor overheats and fails. To prevent this from happening, all existing microcracks are sealed with special thermal paste KPT-8. Dissipating heat to the radiator is the key task that this substance performs.

Replacing thermal paste on the processor and video card of the computer

It seems that you should not pay the same close attention to the choice of thermal paste as to other elements of the computer. But the temperature conditions in the case and, accordingly, the duration of the processor’s operation depend on it. Those who purchased a PC case already assembled should not relax. Over time, the paste becomes less suitable, dries out, and jumps in processor temperature may occur until the system reboots due to overheating.

Where to change thermal paste on a computer? For this question, please refer to the instructions for the motherboard. But if it is not there or there is no Russian language in this brochure, then we will solve this problem together.

Such a thermal interface is necessary to effectively remove heat from the surface of the central processor and fill microcracks to level it. But first you need to choose a paste that makes the processor feel comfortable after applying it.

Thermal paste KPT-8

The most popular thermal paste is type KPT-8. It is domestically produced and is familiar to electronics connoisseurs with thirty years of experience in the former USSR. KPT-8 is the cheapest, but does not require replacement for a long time, which is its advantage. The thermal conductivity coefficient must be at least 0.7 W/(m K) at 20 ºС. The higher the temperature, the lower this indicator - at 100 ºС it reaches a minimum value of 0.65 W/(m K). This paste is made based on GOST 19783-74, but manufacturers interpret it in their own way, therefore, its consistency can be anything from liquid to thick.

Alsil-3 thermal paste

Another Russian thermal conductive paste is Alsil-3. Based on early tests, it gained several degrees over the previous paste KPT-8. The declared thermal conductivity reaches 2 W/(m K), which is its advantage. It is also much thicker, which you can feel when squeezing. On average it lasts for 2 years.

Thermal paste KPT-8: reviews and characteristics

Externally, it is a homogeneous white substance with a thermal conductivity of the order of 0.7-0.95 W/m x K. Moreover, its specific level of electrical resistance is 1014 Ohms (sometimes this indicator may be slightly higher than the specified norm). The operating temperature at which thermal paste does not lose its properties is from minus 60 to plus 300 degrees Celsius. Thus, KPT-8 (reviews also note this point) provides excellent thermal conductivity under any processor or video card load.

How to protect yourself from overheating your computer | Computer wizard

Overheating is one of the most dangerous and common problems with personal computers.

Why does my computer overheat?

The main cause of overheating is dust, which clogs the ventilation holes, which is why the hot air that should come out of the inside of the personal computer remains near the processor (video adapter).

The consequence of overheating is: slow operation, even in the simplest applications and spontaneous shutdowns of the PC. In the case when the protection is triggered, when the critical temperature is reached, a shutdown occurs. If the protection does not work for some reason, you will lose your processor or motherboard.

Above is an example of a system unit that I have never looked at for a long time. Dust has accumulated on the system unit and processor fans.

And here you see how the heatsink holes on the processor are clogged. It is through them that hot air should escape, but when it encounters such a “felt boot” on the way, it of course remains inside, continuing to heat the “stone,” thereby slowing down the operation of the computer.

In addition to dust, overheating may be caused by the fact that your system unit is installed near a central heating radiator, or the ventilation holes on the case are blocked by foreign objects, such as piled-up books, magazines, etc. as a result, air circulation inside the PC case is disrupted, hot air remains inside the system unit.

Cleaning the system unit from dust should be done every 6-12 months. It is enough to open the lid and visually inspect its presence. It is better to collect dust with a vacuum cleaner, but carefully. There is no need to move the pipe inside the system unit like a soldier mopping the floors in an army outhouse. Try not to touch any elements to avoid damaging them.

Thermal paste

Thermal paste is another essential element in a computer cooling system. It provides good thermal conductivity between the processor and the radiator, transferring heat to the latter. Sometimes, just replacing thermal paste with a better one can reduce the processor temperature by 5-15 degrees. Try to use imported thermal pastes (Arctic Coolong, Thermaltake, Cooler Master, Zalman, Noctua, Titan Nano Grease, etc.).

Thermal paste should be applied in a thin layer over the ENTIRE surface where there is contact between the processor and the heatsink. When applying thermal paste, you should not apply the principle “You can’t spoil porridge with oil,” just a thin layer. Sometimes, the manufacturer of high-quality thermal paste includes a special spatula along with the tube for uniform application. Some use a blade or a plastic card.

What is thermal paste for?

When the computer is actively used, some parts of it begin to get very hot. If your system unit or laptop suddenly turns into a hot frying pan, you don’t need to be a computer expert to understand that something is wrong. Overheating affects operating speed, system performance, and the viability of the entire PC as a whole. To extend the life of your computer, you should regularly clean it of dust and change thermal paste.

Do you need thermal paste?

Why do you need thermal paste anyway? Perhaps, let's start answering this question a little from afar. You all know what a processor is. This is literally the heart of the computer. Similar to what beats in your chest, this heart continuously performs many different operations, supports a lot of processes within the system.

During its activity, the processor generates a considerable amount of heat. And, if he constantly works at such high temperatures, he will inevitably die. Try working in such a hot environment every day.

Therefore, every computer is equipped with a cooling system. Most often it is presented in the form of a cooler. A cooler is a radiator with a fan. The first conducts heat from the heating elements of the computer to the second, and it disperses it throughout the room.

Everything seems quite simple, but what does thermal paste have to do with it? Despite the fact that the efficiency of the cooling system directly depends on how quickly the radiator can remove heat from the processor. If the part heats up faster than the heat leaves it, then there will be no benefit from the operation of the cooling system. At the same time, you can’t just take and attach a radiator to the processor - because either air will pass between them, which will only make things worse; or the radiator will simply scratch the chip, which will also not lead to anything good.

This is where thermal paste comes into play. It is the conductor of heat from the processor to the radiator. It “fastens” the processor and the heatsink, allowing the latter to effectively remove heat from the former. If the thermal paste dries out, heat transfer will decrease, the processor will begin to overheat, and the computer, in turn, will slow down or even shut down. Therefore, you need to periodically change the thermal paste to prevent this from happening.

The highest quality thermal pastes for processors

This list contains manufacturers that we recommend considering as a priority.

Deepcool Z9

The Deepcool company produces coolers of various levels and makes thermal paste that can be found included with some cooling systems. Pasta is also available for free sale. Its low price combined with good performance ensures stable interest among buyers.

Deepcool Z9 is a good budget paste

Deepcool Z9 comes in a 3g filled syringe. Suitable for home and office computers and mid-range laptops. According to the manufacturers, thermal paste can withstand temperatures up to 200 degrees. However, this advantage is practically depreciated by low thermal conductivity - 4 W/mK. At such rates, overclocking will require many coolers and fans to prevent the processor from overheating.

Advantages:

- Low cost.

- Special spatula for applying paste.

- Good heat dissipation performance - up to 6-8 degrees.

- Maximum temperature - 200 degrees.

Flaws:

- Too sticky.

- Takes a long time to dry on the processor.

- Not suitable for overclocking due to low thermal conductivity.

Price: from 240 rubles

Zalman ZM-STG2

Zalman ZM-STG2 is one of the best thermal pastes on the market. It is produced by Zalman, a company known for its coolers. ZM-STG paste in a 3.5 g syringe is added to the kit with mid-price segment cooling systems.

Zalman ZM-STG2 can even be used for minimal overclocking

Depending on the cooler, the Zalman ZM-STG2 can provide a temperature reduction of 10-15 degrees. Thermal conductivity - 4.1 W/mK. The maximum temperature after which the paste changes consistency is 150 degrees. This limit allows you to use Zalman ZM-STG2 for minimal processor overclocking. The main thing is not to get carried away too much - after all, this is a budget thermal paste.

Advantages:

- Long-term preservation of properties.

- Effective temperature reduction.

Flaws:

- Thick consistency that is difficult to apply to the processor.

- No tools for applying paste included.

Price: from 335 rubles

Glacialtech IceTherm II

Glacialtech IceTherm II thermal paste is suitable for laptops and gaming PCs without overclocking. Supplied in the form of a 1.5 g syringe. This is enough for one application, maximum two. The syringe is screwed on with a cap, which allows it to retain its properties for some time after opening. The kit also includes a spatula for applying the paste.

Glacialtech IceTherm II - an inexpensive solution for powerful computers

The nominal thermal conductivity of Glacialtech IceTherm II is 8.1 W/mK, but in reality the value is slightly lower. Nevertheless, thermal paste can reduce the processor temperature by 10-15 degrees, depending on the activity of the cooler. Cooling takes just a few minutes. The maximum temperature is only 100 degrees. It cannot be used for overclocking.

Advantages:

- Good equipment.

- High thermal conductivity, which lasts for a long time.

- Does not delaminate even on high-temperature chips - for example, on video cards.

- The consistency is easy to work with - liquid enough to apply and not liquid enough to spread.

Flaws:

- Low operating temperature.

- Thermal conductivity does not correspond to the declared level.

- High cost, taking into account all the main indicators.

Price: from 410 rubles

Arctic Cooling MX-4

Arctic Cooling MX-4 thermal paste comes in two forms - a small 4 g syringe for personal use or a large 20 g container for service centers or specialists who regularly assemble and maintain PCs. Unfortunately, in neither case are there tools for applying the paste included.

With Arctic Cooling MX-4 silicon paste you eliminate the risk of short circuits

Arctic Cooling MX-4 is designed for computers with a powerful cooling system. If you have a powerful cooler, the paste allows you to maintain the temperature at 40-50 degrees even for multi-core gaming and overclocked chips. Thermal conductivity is high - 8.5 W/mK. The consistency is almost ideal, medium in thickness, not viscous. The upper temperature limit is 150-160 degrees.

Advantages:

- Ceramic paste that eliminates the risk of short circuiting.

- Excellent thermal conductivity.

- Various packaging options.

- Optimal viscosity for application and removal.

- Suitable for overclocking the processor.

Flaws:

- Relatively high cost.

- Poor equipment - no tools for application or removal.

- Not suitable for chips that constantly operate at high temperatures, such as video cards.

- Loses properties and delaminates under thermal stress.

Price: from 500 rubles

Noctua NT-H1

Noctua NT-H1 thermal paste was developed by scientists at an Austrian university studying heat transfer. Often supplied with Noctua coolers, but also sold separately. The paste is located inside a 3.5 g syringe with a screw cap, which prevents drying out during long-term storage.

Noctua NT-H1 is suitable for powerful but not overclocked processors

Noctua NT-H1 is suitable for home and office computers, as well as gaming machines with non-overclocked processors. The paste has a rather thick consistency, but due to its good stickiness it is convenient to apply in thin layers. Thermal conductivity - 4.5 W/mK. The maximum temperature is 110 degrees.

Advantages:

- Easy to apply consistency.

- Good equipment: a spatula for application, packaging with a screw cap.

- Long-term preservation of thermal conductivity properties.

Flaws:

- Low peak operating temperature - up to 110 degrees.

- Low recommended operating temperature - up to 90 degrees.

- Average thermal conductivity values.

Price: from 500 rubles

Thermal Grizzly Kryonaut

Thermal Grizzly Kryonaut is a traditional thermal paste based on metal particles and silicone oils. However, when developing the substance, a special composition is used, which ensures high thermal conductivity - 12.5 W/mK, as well as durability.

The Thermal Grizzly Kryonaut has one of the highest thermal conductivities among non-professional thermal interfaces

Thermal Grizzly Kryonaut is suitable for gaming computers, including overclocked and liquid-cooled machines, graphics cards and high-end laptops. Thermal paste is supplied in syringes with a volume of 1 or 5 g. In both cases, the kit includes a spatula for distributing the substance throughout the processor.

Advantages:

- High thermal conductivity. The best result among metal-silicon thermal interfaces.

- Easy application and removal.

- Suitable for overclocked processors and video cards.

- Provides significant and rapid temperature reduction.

- Retains thermal and performance characteristics even several years after use.

Flaws:

- High price.

- Air dries quickly.

Price: from 630 rubles

Thermal Grizzly Conductonaut

Conductonaut is the flagship paste from the German company Thermal Grizzly. It is in great demand among users who overclock the processor. Supplied in a syringe with a volume of 5 g. The kit includes a special nozzle, cotton swabs, wipes for degreasing the surface and documentation.

Thermal Grizzly Conductonaut - professional paste based on liquid metal

Thermal conductivity of Thermal Grizzly Conductonaut is 73 W/mK. When applied, the product adheres perfectly to the surface, and after heating, a minimal layer remains. Taking into account the features of the cooler, the substance can lower the temperature by 10-15 degrees. All this makes thermal paste one of the best solutions for overclocking a processor and video card.

Advantages:

- Excellent thermal conductivity.

- Rich equipment.

- Good viscosity.

- Leave a minimal layer after warming up.

Flaws:

- High current conductivity.

- Aggressive to aluminum, can only be used with radiators with a copper base.

Price: from 720 rubles

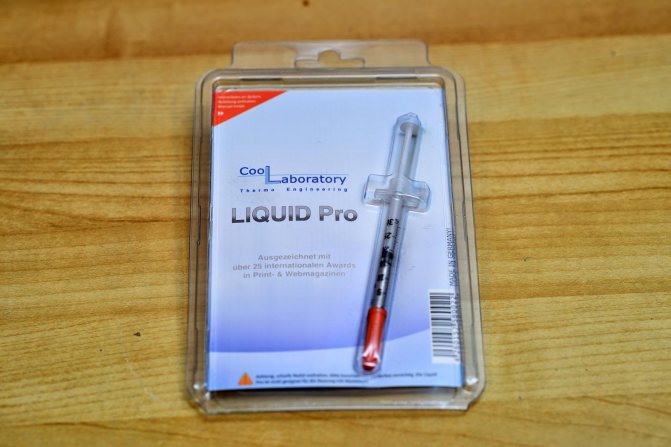

Coollaboratory Liquid PRO

Coollaboratory Liquid PRO is a professional thermal paste based on liquid metal. Supplied in a 1 g syringe. The kit also includes special cotton swabs and a sponge for applying the substance. Suitable for users who engage in extreme overclocking of components.

Coollaboratory Liquid PRO - thermal paste with the highest thermal conductivity

Thermal paste is made without the use of solid inclusions and silicone oils, due to which it offers the highest possible thermal conductivity - 82 W/mK, as well as maximum durability. Even with constant exposure to high temperatures, Coollaboratory Liquid PRO retains its performance properties, so it can be used in high-performance laptops, video cards, overclocked processors with liquid cooling systems.

Advantages:

- Maximum possible thermal conductivity.

- Excellent kit, which includes all the necessary tools for high-quality paste application.

- Long-term preservation of thermal and operational properties.

Flaws:

- High price.

- Difficult application procedure.

- Reacts with aluminum and is therefore only suitable for radiators with a copper plate at the base.

- High electrical conductivity.

Price: from 850 rubles